2. Process flow

De-coiling--feeding---forming---cutting---finish product

3. decoiler(You can choose it)

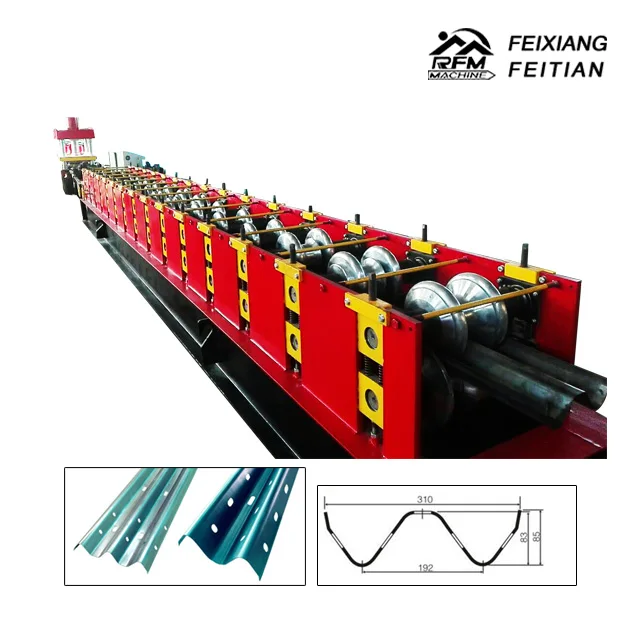

4.Forming device

1>Main moter power: 18.5KW

2>Hydraulic station power: 11KW

3>Hydraulic oil pump: CB-E310

4>Sprocket: P-50.8

5>Roller station: 16

6>length of production line: 12m

7>Diameter of principal axis: 95MM

8>Material of roller: GCr15

9>Processing speed: 6-8m/min

10>Thickness: 0.3-4mm

11>hydraulic oil pump: CB-E310

12>material of blade: Cr12

13>Equipment parts: 5T decoiler, roll forming machine, punching machine, leveling machine, hydraulic cutter, hydraulic station , computer control system, counter.

5. Hydraulic Cutting device

6.Control Device

1>Screen: Detla screen

2>Automatic length measurement

3>Automatic quantity measurement

4>PLC is used to control length and quantity. Machine will automatically cut to length and stop when required quantity is achieved

5>Length inaccuracy can be amended easily

7. Simple output

Packaging & Shipping

8.package and loading

Our Services

9.Payment and terms

1>30% T/T in advance and balance 70% after inspection confirmation before shipment.

2>Quotation will be valid with in 30 days.Final price should be confirmed.

3>Delivery time : Within 45 working days after receiving deposit.

10.Warranty

1>One year, and we will provide the technical support for the whole life.

2>Training: the buyer should be responsible for visa, return ticket, food and accommodation overseas and USD50/person/day for salary.

3>Need one technicians

4>Training time: one week (contains the time of installation and adjustment)

Company Information

11.Our certificate:

12.Our customers:

13.Our factory:

14.Contact information:

We have been in this industry for years and have cooperated with customers from all over the world.For more,pls contact me.

没有评论:

发表评论