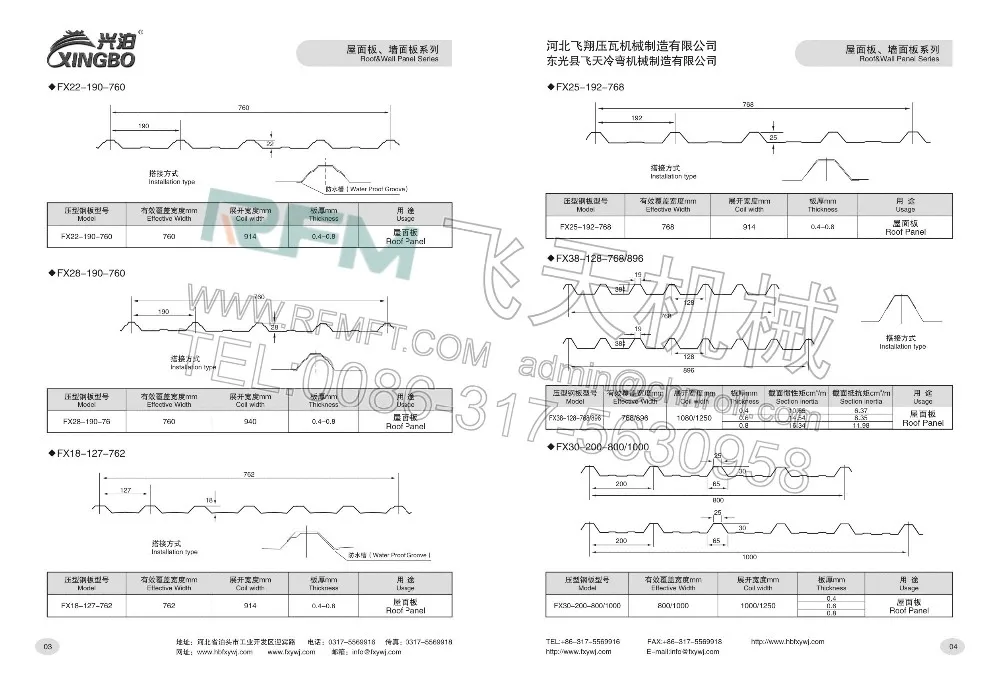

Feixiang feitian Trapeze Metal Roll Forming Machine

Product Description

1.Processes and components

Processes: Man-made uncoiler—Roll forming machine—PLC system-Hydraulic system-Blade—Receiving table

Flow chart:

Main technology:

1.

|

Raw Materil

|

PPGI,PPGL, GI,GL

|

2.

|

Thickness

|

0.3-0.8mm

|

3.

|

Uncoiler

|

5 Tons Manual Uncoiler

|

4.

|

Roller Station

|

11 Steps

|

5.

|

Shaft Material

|

70mm And No.45 Steel

|

6.

|

Roller Material

|

No.45 Steel

|

7.

|

Transport

|

Chain Transport

|

8.

|

Forming Speed

|

8-12m/min

|

9.

|

Motor Power

|

3KW

|

10.

|

Voltage

|

380V 50HZ 3Phase

|

11.

|

Cutting System

|

Hydraulic Cutting

|

12.

|

Control System

|

Detal PLC

|

ptional Choice

1.

|

Electric Uncoiler/Hydraulic Uncoiler

|

2.

|

Robstic Structure

|

3.

|

Automatic Stacker

|

4.

|

Logo Punching Machine

|

5.

|

Safety Cover

|

Detailed Images

♦ Manual Decoiler

1.

|

Material Coil Inner Diameter 450-550mm

|

2.

|

Max Material Coil Outer Diameter 1500mm

|

3.

|

Max Raw Material Width 1250mm

|

4.

|

Loading Capacity 5 Tons

|

♦ Frame

Structure

|

Middle Plate Welded

|

Material

|

H Steel

|

♦ Feeding Table

1

|

Leveling And Straightening Rollers

|

2

|

Raw Material Feeding Location Slot (Adjustable)

|

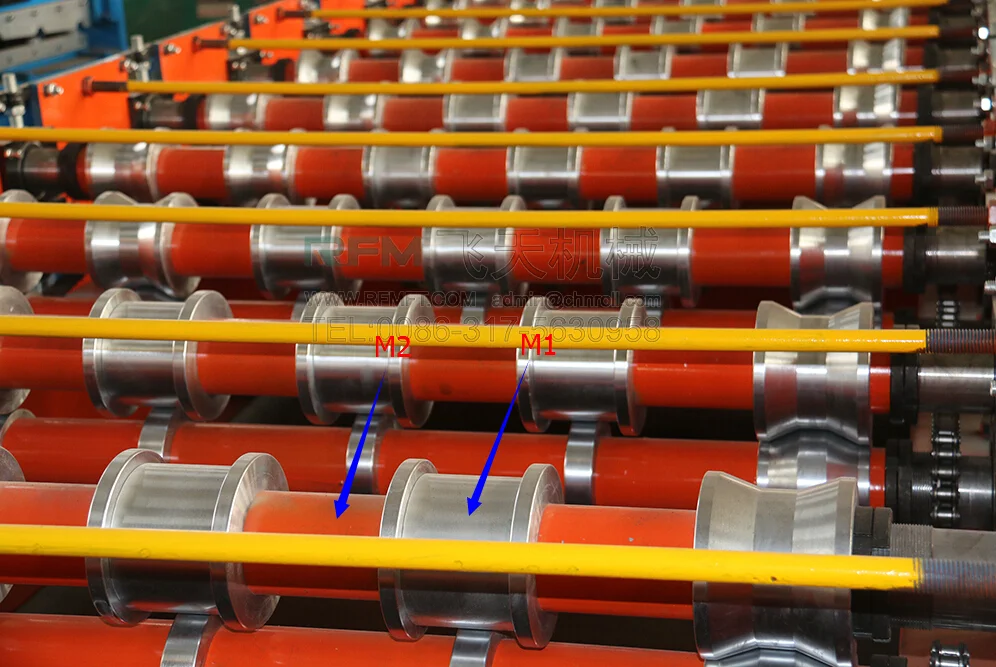

♦ Roller / Shaft

M1

|

Material No.45 Steel With Chrome Coating

|

M1

|

With Heat Treatment

|

M1

|

Between Two Rollers Have Spacer Bush

|

M2

|

Material No.45 Steel

|

M2

|

70mm Diameter

|

M2

|

With Heat Treatment

|

M2

|

Between Rollers And Shaft Have Locking Washers And Nuts

|

♦ Cutting System

1.

|

Hydraulic Automatic Cutting

|

2.

|

Blade Material Cr 12 With Quenched

|

3.

|

No Burring And Painting Damage

|

♦ Comtrol System

M1

|

Transducer

|

M2

|

PLC System

|

M3

|

Control Whole Line Forming Speed

|

M3

|

Control Oil Pump

|

Certifications

Packaging & Shipping

Main machine: all rollers will be brushed unti-rusty oil, and packed with waterproof plastic film

Control box: be packed with thick cardboard, and outer side thick waterproof plastic film

All parts inside container will be fixed very well which can keep safety and fixed for long time sea transportation

Control box: be packed with thick cardboard, and outer side thick waterproof plastic film

All parts inside container will be fixed very well which can keep safety and fixed for long time sea transportation

Our Services

1. Professional mechanical background sales for better undestanding customer's need

2. Experienced in China machine industry for supplying comprehensive machines and equipments

3. Strictly product manufacturing and quality controlling to ensure every machine we sold is satisfied with our customer

4. Engineers available to service machine overseas, for example installation, training, etc

5. Lifelong service for spares, ware parts, technical supporting, etc

Contact me Bunny

没有评论:

发表评论