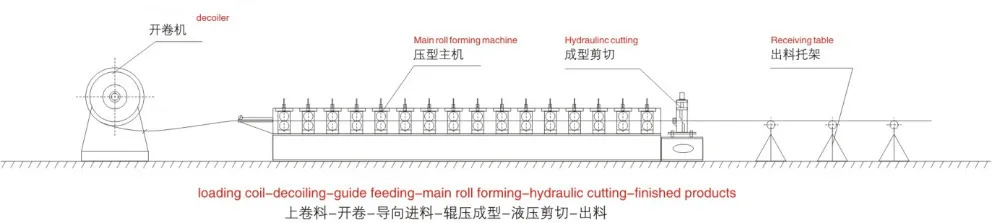

The T-bar Roll Forming Machine, which is manufactured in Hebei Feixiang Roll Forming Machinery Co.,Ltd, are manufactured since 1988. The best known is the linear ceiling 0.8mm profile, but there are many other types as well as shapes. The producing speed can be 10-15m/min, which is so well-known in European countries. The line consists of the following elements:

· Decoiler

· Main roll forming machine

· Hydraulic cutting system

· Unloading table

· Set of additional rollers or ready mounted on the machine

The line has the advantage of offering everything needed to produce a complete suspended roofing within a compact space and it is undoubtedly the best investment for start up companies entering the world of suspended ceilings.

In addition to this compact line we also manufacture high-output lines with for very wide panels.

Please contact our technical-sales office. We will be happy to give you all the information you require.

Please contact our technical-sales office. We will be happy to give you all the information you require.

Warranty

1). One year, and we will provide the technical support for the whole life.

2). Training: the buyer should charge of visa, return ticket, food and accommodation

overseas and USD50/person/day for salary

3). Need one technicians

4). Training time: one week (contains the time of installation and adjustment