HEBEIFEIXIANG-Roller shutter slates roll forming machine

Product Description

Summary1). To design and make the best roll forming machine, we took EUROPEAN quality standard;

2). Choose the best material and components, and adopting our 17+ years experience;

3). We achieves that the machine capacity is double of the competitors;

4). The machine working speed can be 60m/min;

5). Very easy to install and operate the roll forming machine.

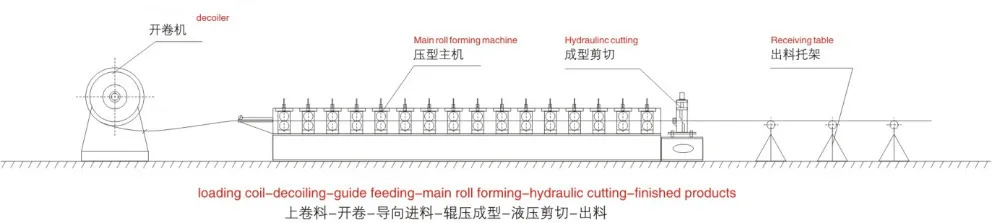

Machine working flow:

Machine Technical Specifications:

About raw material and product for roll forming machine

| Material&product | Feeding width | according to profile |

| Effective width | according to profile | |

| Raw material | galvanized steel strip | |

| Thickness | 0.3-0.7mm | |

| Yield strength | 280-350 MPA |

How to load the material??→Decoiler

| Manual decoiler | Inner diameter:450-550mm | Expand by band |

| Outer diameter:1500mm | ||

| Max Coil width:300mm | ||

| Capacity: 1.5T | ||

| Decoiler dimension:1.5*1.5*1.5m | ||

| Decoiler weight:355KGS | ||

| Quantity: 1set | ||

| Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system | ||

What the main forming machine will be???→as below

| Main Forming machine | Forming steps | 12 steps |

| Shaft diameter | 50mm | |

| Machine stand | Individual Arch Plate | |

| Machine frame | steel plate welded | |

| roller material | Cr12 | |

| shaft material | 45# steel with quenching and tempering | |

| Work speed | standard: 20---25m/min; 45---60m/min | |

| Transport | By gear | |

| Power of main machine | 4kw | |

| Voltage | 380V-50HZ-3P(as required) | |

| Machine dimension | 5.5*0.8*1.5m | |

| Machine weight | About 2.5T | |

| Machine color | Yellow and blue(as required) | |

| Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working Feature : Ensure stability , precision and lifetime. | ||

Packaging & Shipping

Main machine: all rollers will be brushed unti-rusty oil, and packed with waterproof plastic filmControl box: be packed with thick cardboard, and outer side thick waterproof plastic film

All parts inside container will be fixed very well which can keep safety and fixed for long time sea transportation

Our Services

We will do the trust worthy services for every customer!

没有评论:

发表评论