High Speed CU Metal Stud and Track Light Keel Roll Forming Machine

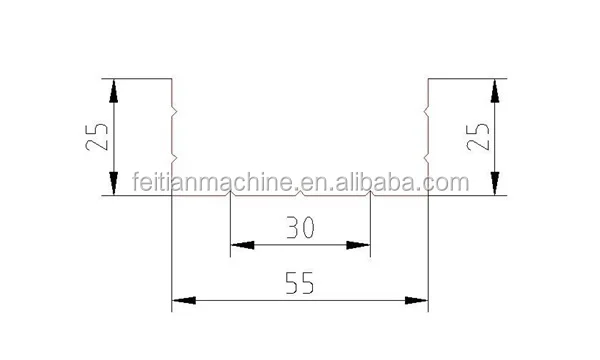

Profile drawing :

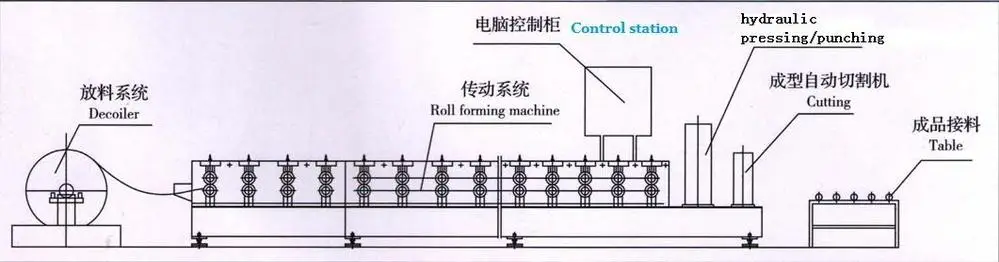

Process flow:

De-coiling→leveling→feeding→forming→ punching → cutting→product

Technical parameters :

Manual decoiler

|

1).Material coil inner diameter: 450mm-550mm

2).Max coil width:300mm

3).Carrying capacity: 1.5T

|

Forming device

|

1)Shaft material:high grade No.45 steel after treatment

2)Out diameter is40 mm

3)Roller material: 45# steel polished and coated with chrome HRC55-60°

4)Forming speed:25-40m/min

5)Main motor power:5.5 kw

6)Roller station:11stations

7).Voltage:380v,50Hz,3 phase

|

Hydraulic cutter

|

1). material of blade: Cr12 mould steel with quenched treatment 55-60°C

2). cutting system: adopt advanced hydraulic drive, after forming automatic

cut, no distort, no wasting , high safe factor.(main motor stop cutting)

|

Control system

|

Type: PLC Frequency Control System with touch screen

PLC Brand: Japan Panasonic Encoder Brand: Omron

Length Error: ±2mm

|

Outpur table

|

It is simple and used to load finished product.

Length:6m

|

Spare Parts

|

1).Easy damaged parts: conk 2 pcs, fuse-link 4 pcs

2).Rubber mat 1 pcs;

3).Bolt spanner 1 pcs

|

Photos :

This kind of machine has the best quality and the best price. It has accurate measurement

and easy operating. We can design and manufacture the special type machine according to

the customers’ requirement and we could provide technical guiding, production, installation,

debugging and maintenance service to all customers.

Application prospect

Application prospect :

The feature looks beautiful ,elegant and noble .

Those are widely used in building the factory, hotel , and mobile house and so on.

Packaging & Shipping

Packaging and Shipping :

Container

|

1*20 container

|

Packaging

|

Nude and export regular package,any special request as clients’ requested

|

Fixation

|

Every part will be fixed by wire and welded before shipping.

|

Our Services

Service :

Our factory is professional manufacturer in China, other products :

single layer roll forming machine,

double layer roll forming machine,

glazed tile roll forming machine,

purlin roll forming machine,

stud and track roll forming machine

highway guardrail roll forming machine,

door frame roll forming machine,

ridge cap roll forming machine,

floor deck roll forming machine,

sandwich panel roll forming machine,

Russian C&H-type roofing and wall panel formig machine ,and so on

Terms

Terms:

Payment terms

|

Payment :30%T/T in advance and balance 70% after inspection confirmation before

shipment.

|

Delivery time

|

within 45 working days after receipt of deposit

|

Warranty

|

One year, and we will provide the technical support for the whole life.

|

Training

|

1). Training: the buyer should charge of visa, return ticket, food and accommodation . overseas and USD100/person/day for salary.

2). Need one technicians

3). Training time: one week (contains the time of installation and adjustment)

|

Validity time

|

Validity of the quotation is 30 days

|

Company Information

About us :

Contact way

Contact way :

If you have any question ,please contact me.I'm Rita,I will serve for

you 24 hours!

Besides,welcome to visit our company.Seeing is believing.

没有评论:

发表评论