2017年3月31日星期五

T-bar Roll Forming Machine

Color Stone Coated&Sandwich Panle Machine

Shutter Door and Door Frame Roll Forming Machine

T-bar Roll Forming Machine

2017年3月29日星期三

The 121th China Import And Export Fair

The 121th China Import And Export Fair

第121届中国进出口商品交易会

Date:04/15/2017-04/19/2017

Venue:China Import and Export Fair Complex

(No.380,Yuejiang Zhong Road,Guangzhou)

Booth:A1.1 G36

2017年3月28日星期二

2017年3月24日星期五

Which is a high quality manufacturer of roll forming machine

Hebei Feixiang Roll Forming Machinery Co.,Ltd was founded in 2007.The registered capital of 4 million yuan.The existing staff of 290 people.Covers an area of 36800 square meters,With two factory and an office,Industry number 11 in the country.Our factory is specialized in manufacturing C\U Keel roll forming machine,color steel forming machinery ,C&Z purlin machine,Glazed tile forming machine,steel structural floor panel roll forming machine,sandwich panel roll forming machine,highway guardrail forming machine and other cold roll forming machines.

Gsm:+86-18603172161 E-mail:admin@chnroll.com

Our Team

2017年3月22日星期三

Keel roll forming machine

keel roll forming machine

Advantages:

♥ In Botou, we are the first to do pressure roll forming machine export business

♥ As a manufacturer we are specialized in all kinds of roll forming machine.

♥ Good experience of 20 years to make roll forming machine.

♥ Good experience for export more then 40 countries.

♥ Provide best price,good quality and fast delivery.

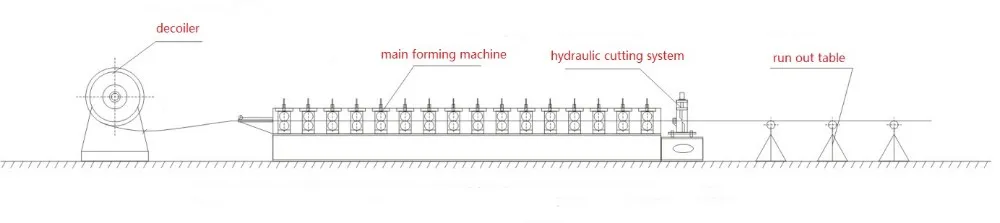

Process Flow

De-coiling →feedinig→forming→step-formed mechanism →cutting →product

Product Description

Parameter

1

|

Model No.

|

keel roll forming machine

|

2

|

Thickness

|

0.3-0.8mm

|

3

|

Coli material

|

GI

|

4

|

The bearing capacity of manual decoiler

|

6.5 tons

|

5

|

shaft material

|

45#steel

|

6

|

Out diameter

|

Customized

|

7

|

numbers of forming steps

|

Customized

|

8

|

transmission

|

chain transmission

|

9

|

Forming speed

|

10-15m/min

|

10

|

main motor power

|

3kw

|

11

|

voltage

|

380V50HZ Three-phase or as required

|

12

|

dimension

|

5*1.3*1.3

|

13

|

cutting

|

hydraulic cutting

|

14

|

blade material

|

Cr12 steel with quenched treated 60-62°c

|

15

|

control system

|

PLC(Delta)

|

16

|

length tolerance

|

±1mm

|

17

|

spare parts

|

1 easy demaged parts:conk 2pcs, fuse-link 4pcs

2 rubber mat: 1 pcs

3 bolt spanner: 1 pcs

|

18

|

The whole line including: Manual decoiler, roll forming machine, hydraulic station,

hydraulic cutter, PLC control system, run-out table.

| |

Spare parts

Decoiler:

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Inner diameter:350-450mm

Outer diameter:450mm

Coil width:300mm

Capacity:1.5T

Hydraulic oil pump

Advanced hydraulic system from Taiwan

Usage: It is used to provide power for cutting devices.

Power: 3kw

PLC control station

Usage: Automatic length and quantity measurement.

Screen: touch screen

Frequency:Delta

PLC control

PLC:Delta

Run out table

1 set with 3 meter’s long.

Related Products

2017年3月21日星期二

China Manufacturer Galvanized Metal Gypsum Board Suspended Ceiling Joist Silhoutte T Bar Roll Forming Machinery

Product Description

We are the professional manufacturer for cold roll forming machine in the north of China.

The machines have been exported to more than 40 countries and achieved good performance.

Certificated of CE ISO can offer to client.

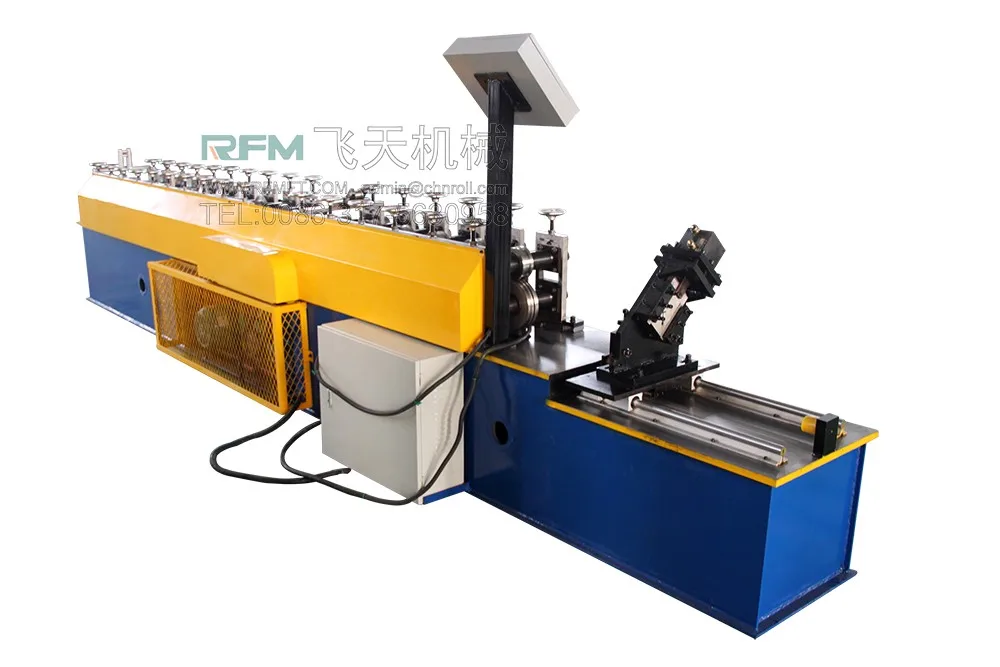

T-bar Roll Forming Machine

| Technical parameter | ||

| 1. | working process | decoiling-feeding-forming-cutting-product |

| 2. | raw material | galvanized sheet |

| 3. | material thickness | 0.3-0.8mm |

| 4. | roller material | GCr15MoVo |

| 5. | shaft material | 45#steel outer diameter:40mm |

| 6. | cutting system | hydraulic |

| 7. | control system | PLC(Delta touch screen) |

| 8. | warranty | ong year, and we will provide technical support for the whole life |

| 9. | others | after the machine is finished, we will inform customer to check the machine in my workshop and test the machine before shipment. |

Noted:main working units contain the decoiler, main forming machine, cutting system, control system and the run out table.

Machine details please find the following pictures:

1.Decoiler: three types for customer's choice

1. 1.5T manual decoiler

2. 5T electric decoiler

3.5T 7T 10T hydraulic decoiler

2.Forming process

3.Cutting system and control system

1. advance hydraulic cutting, no wasting and no distorting, low sounds

oil pump for one set and the motor power is 5.5kw

2.PLCcontrol with Delta touch screen

computer control length and quantity, after forming automatic cutting to length and stop when required quantity is achieved.

Noted: the language can be done in Chinese, Russia, English and so on.

4.Run out table

1. simple 3 meter's long run out table (we suggest this one is better used)

2. automatic stacker(we can offer 6m, 9m, 12m)

订阅:

评论 (Atom)